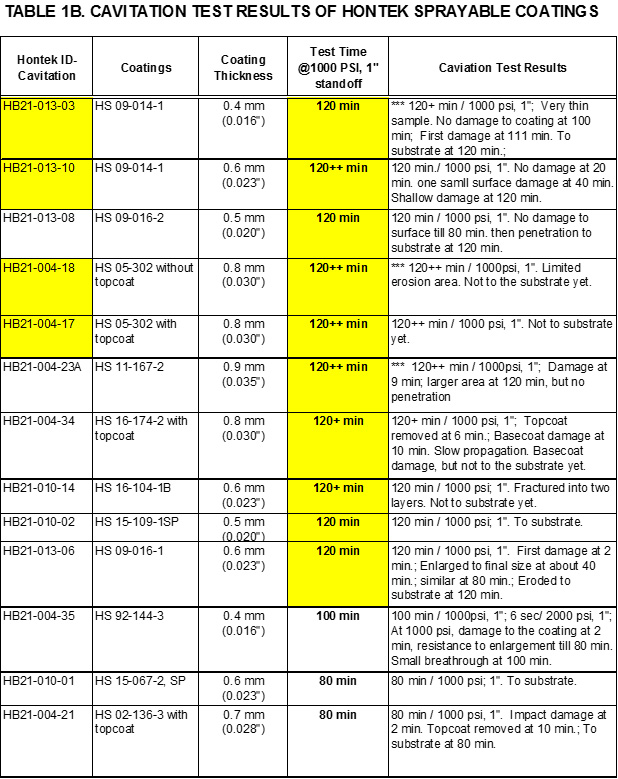

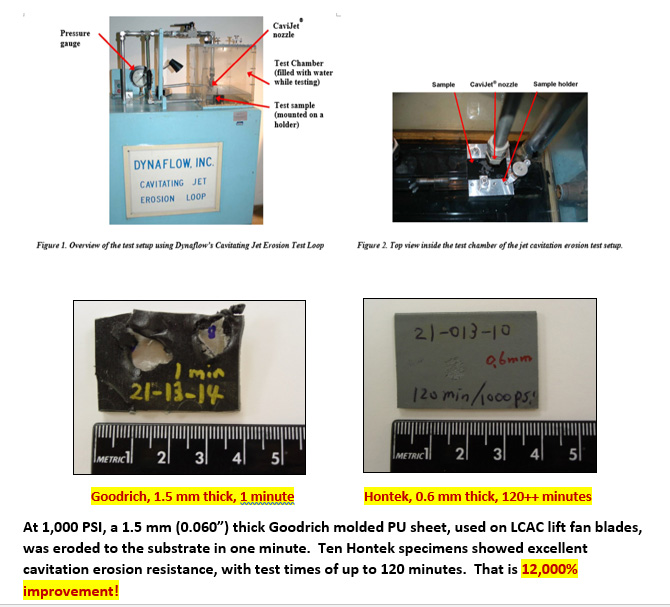

Hontek coatings have demonstrated far superior cavitation erosion resistance than competitive products. Cavitation tests were conducted at Dynaflow, Inc. using equipment as shown in Figure 1 and Figure 2. Test condition was 1,000psi jet pressure, with one inch stand off distance.

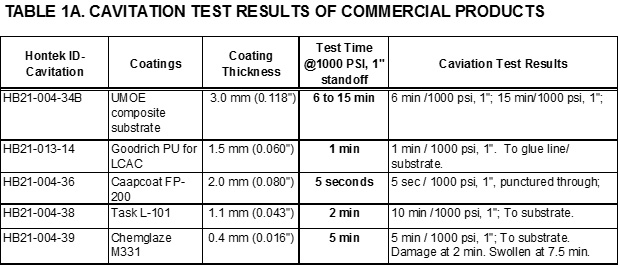

1. Goodrich LCAC Molded Sheet (Specimen HB21-013-14)

Goodrich LCAC material, MYCYMWO, 0.060” thick, with self-stick adhesive, was tested as control. The material has very poor cavitation erosion resistance. At 1000 psi, 1” standoff distance, the 1.5 mm (0.060”) thick molded sheet was punctured through in one minute. At 4 minutes, clean metal substrate was seen.

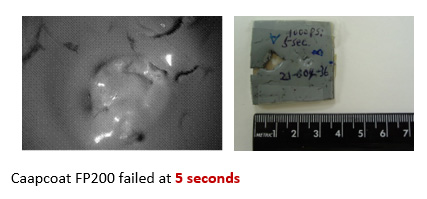

2. Caapcoat FP200 Basecoat (Specimen HB21-004-36)

Caapcoat rain erosion resistant coating FP-200 is widely used in the aerospace industry. It has fair rain erosion resistance. A 2.0 mm (0.080”) thick was punctured through in five seconds at 1000 psi, 1” standoff distance.

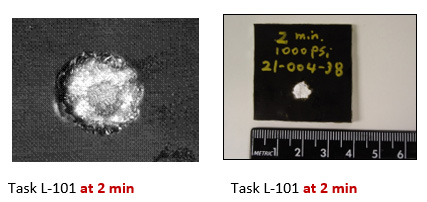

3 Task L-101 Molded Boot (Specimen HB21-004-38)

Task L-101 was a molded boot material used by the U.S. Army in erosion protection of helicopters rotor blades. At 1000 PSI, 1” standoff distance, a 1.1 mm (0.043”) thick Task L-101 molded boot was eroded through in 2 minutes. The material has very poor cavitation erosion resistance.

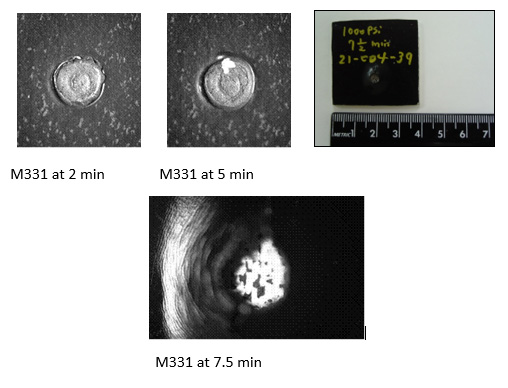

4. Lord Chemglaze M331 (Specimen HB21-004-39)

Chemglaze M331 is a rain erosion resistant coating sold by Lord Corporation. In the cavitation test at 1000 PSI, 1” standoff distance, a 0.4 mm (0.016”) thick Chemglaze M331, bonded onto an aluminum sheet with epoxy adhesive, was damaged at 2 min, then eroded to the substrate in 5 minutes. At 7.5 minute, the damaged site was swollen.

5. HONTEK SPRAYABLE COATINGS- see table below