Hontek has developed moldable resins for forming the preformed shapes, such as “boot”, “sock”, “soft shell”, etc. These molding resins have demonstrated exceptional resistance to rain erosion, sand erosion, and combined sand and rain erosion. It is well known fact that slight roughening of a coating surface by sand particle will cause accelerated failure in rain. Hontek elastomers have exceptional durability not only in rain, but also excel in the double severe (sand + rain) erosion. Even more, in the triple severe (rain + sand + rain) erosion.

Rain test was conducted at UDRI. Test speed was 500 miles/hr (232.3 meter/sec), rainfall rate was 1 inch (25.4mm) /hr, 2mm raindrop size. Sand erosion test was 350 mph, 30 degree angle, with 177-350 microns sand, with total sand mass load of 10.9 grams/cm 2 .

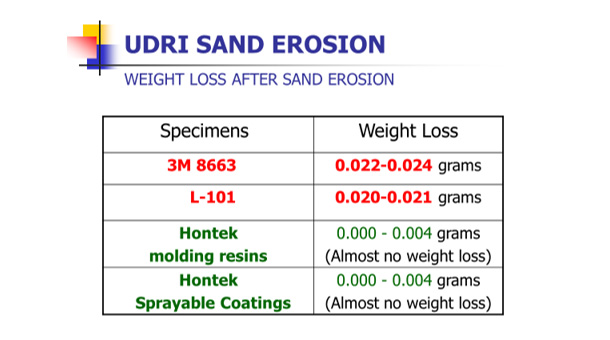

In the following table, the weight loss is the amount of the material lost after one round of sand erosion test. As shown, Hontek molding resins and sprayable coatings show much lower sand erosion weight loss (0.000-0.004g ) than 3M 8663 tape (0.022-0.024g)- a factor of up to 20 times.

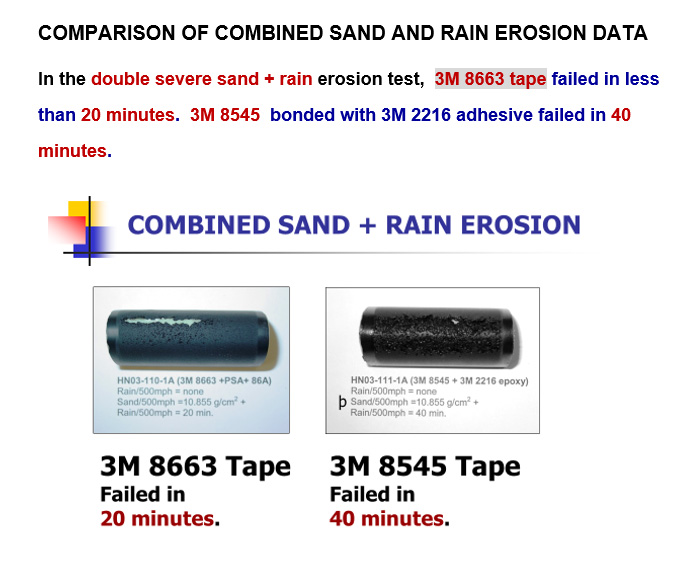

In comparison, in a Triple Severe rain + sand + rain erosion test, Hontek molding resins last more than 300 minutes without penetration to the surface.

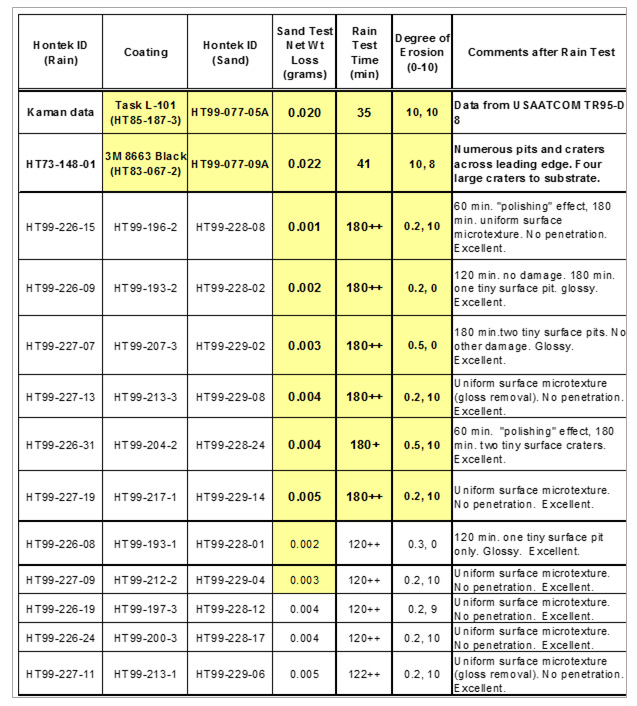

ELEVEN HONTEK MOLDING RESINS – Combined Sand and Rain Test Results

The following table lists the test results of 11 Hontek molding resins. In combined sand and rain erosion tests, the molding resins have shown excellent durability of 180 minutes with very little damage. All of them are far superior to 3M 8663 and 3M 8545, and Task L-101.

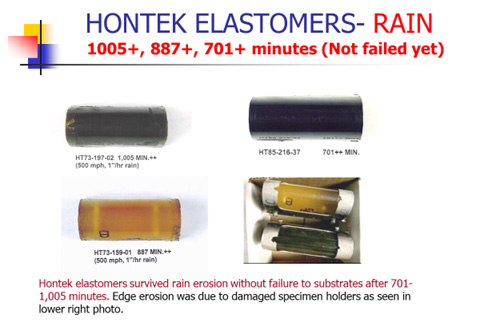

Other Hontek molding resin samples were rain tested to up to 1, 005 minutes. This is incredible rain erosion resistance at 500 mph, 1”/hr rainfall and 2” raindrop size.